SQ/2 Scorpion

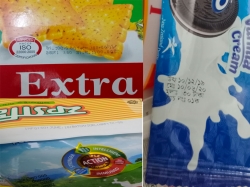

The SQ/2 Scorpion Drop on Demand Large Character Printing System

The SQ/2 Scorpion industrial large character ink jet printer includes upgraded software delivering more features. SQ/2 Scorpion users have the option of choosing from several print head configurations. Five different print head sizes are available, offering 12 print sizes ranging in height from 3/8″ up to 1 3/4″. The 1600 Series print heads offer split-line capability and the option of printing full-size characters or half-size characters with the same print head.

True Versatility for Your Needs

SQ/2 Scorpion users have the option of choosing from several printhead configurations. Five different print sizes are available: 3/8”, 1/2”, 3/4”, 1” or 1-3/4” character height. All printheads are capable of printing at 100% or 70% character height, offering 12 print sizes ranging from 1/4” to 1-3/4” in height. The 1” and 1-3/4” (1600 Series) printheads even offer split-line capability and the option of printing full-size characters or half-size characters with the same printhead.

More Brain. More Brawn.

The SQ/2 Scorpion is upgraded with software features that ink jet users need most: increased memory locations for up to 128 messages, the ability to automatically print a manufacturing date and an expiration date, as well as a shift organizer to automatically separate and code different work shifts within your packaging operation. The SQ/2 Scorpion also comes standard with a shaft encoder input for packagers using a variable speed conveyer. On the hardware side, the SQ/2 Scorpion features a built-in central air gauge to view regulated air pressure within the system and fine-tune your print quality.

| Specification | Value |

|---|---|

| Brand | Squidink |

| Printer Type | Large character ink jet printing system |

| Printhead Options | Users have the option to use up to two SQ/2 printheads, or one 1600 Series printhead |

| Character Heights | SQ/2 Series Printheads (7-channel dot matrix characters) .75” (1.9cm) in 7 x 5 matrix; .5” (1.3cm) in 5 x 5 matrix, or .5” (1.3cm) in 7 x 5 matrix; .375” (1.0cm) in 5 x 5 matrix, or .375” (1. |

| Character Set | 61 character ASCII set Print Speed – Up to 200 feet/minute (61m/minute) line speed |

| Message Length | 128 character length per message; 128 memory locations |

| Communication | RS-232C, 9600 baud, 8 data bits, 1 start, 1 stop, Asynch |

| Software Features | Counter, lot counter, 24-hour clock, 8 or 12 hour programmable shift code, Julian date, 3-letter month name, 3-letter weekday name, expiration date, expiration month, expiration day, expirati |

| Operating Features | Dot size, print delay, character width, photocell on/off/repeat, invert print, reverse print, purge routine |

| Shaft Encoder Output | Resident software allows communication with shaft encoder for use with variable speed conveyors |

| Controller Dimensions | 12” (31cm) H x 12” (31cm) W x 5.25” (13cm) D |

| Controller Weight | 10.5 lbs. (4.8kg) |

| Printhead Dimensions | SQ/2 Series Printheads: 3” (7.6cm) H x 1.6” (4.1cm) W x 7” (17.8cm) L 1600 Series Printheads: 2.5” (6.4cm) H x 1.5” (3.8cm) W x 7” (17.8cm) L Dimensions are for the printhead only – an additi |

| Product Sensor | Diffuse beam photocell (24v) or hardware sinking signal |

| Communication Interface | Two RS-232 ports for connection to input device, host PC, and PLC for input from scale, scanner or external alarm |

| Air Pump | Internal air pump module provides necessary air pressure; external air not recommended |

| Electrical Requirements | 90-120 VAC, 50/60Hz, 4.0 amp |

| Cabinet Construction | Industrial gauge coated steel |

| Operating Environment | Water-Based Ink: 32ºF (0ºC) to 120ºF (50ºC) Solvent-Based Ink: 0ºF (-18ºC) to 120ºF (50ºC) |

| Substrate Capabilities | Porous or Non-Porous surfaces |

| Ink Capabilities | Porous: Squid Ink SQ-60 no-clog ink Non-Porous: Several Squid Ink solvent based fluids to meet your application needs for adhesion and dry time |

| Ink Volume – | .5 gallon (1.9 liters) bottle standard; available upgrade (water-base ink only) to 5.0 gallon (18.9 liters) pail |

BENEFITS OF THE SQ/2 SCORPION

-

Upgraded features include increased message locations, expiration date, shift organizer and encoder input

-

Built-in air gauge to view regulated air pressure within the system and fine-tune print quality

-

Proven plunger technology ensures uptime and keeps maintenance costs to a minimum

-

Two models: water-based for porous surfaces or solvent-based for non-porous surfaces

-

Ability to run two SQ/2 Series print heads or one 1600 Series print head

-

Component modularity eliminates the need for service calls and minimizes downtime; print heads and components can be replaced in less than 5 minutes

| Name | Document |

|---|---|

| Catalog | Download |